Prototyping is a new toy maker! This is a very crucial process when referring to fishing for ideas so anyone can create and be original. This is the point in time that we are bringing our drawings, pictures or plans into reality so it becomes visible and physical. Prototyping allows us to verify our design before it is scaled and the designs are shared with others.

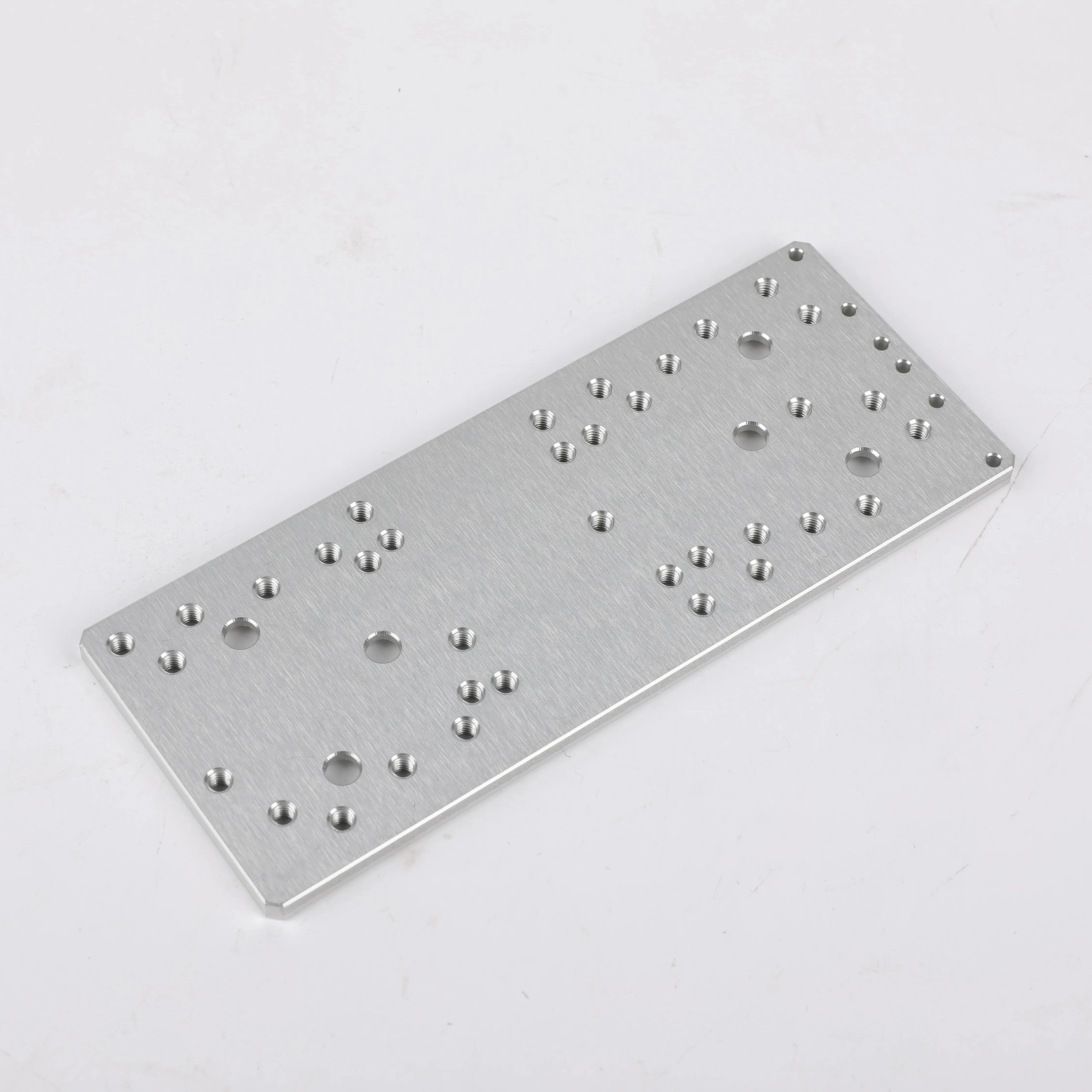

The most important aspect to consider is the materials at our disposal when doing a prototype. We must choose the proper stuff to form our prototype. There are various types of devices used to mold them into the desired form or structure that we think about. There are multiple methods to prototype. Many of these desire-formed incarnations are printed by 3D printers, which print the shapes we be quantifiable layer over utterance. Some use special machines, like a CNC machine which can cut and shape materials very effectively. A strong laser which can cut through materials is also employed by some individuals. Either way we make sure that in the end, it looks just like how we originally thought of and as long as its somewhere close to ours at least so then we know our idea is straight official.

Before they go into mass production of their ideas, such as designing the latest must-have product or gadget; thinkers (designers) want to know that whatever it is going to work. Including this is the reason why prototyping exists in designing stages. By having a prototype they test their design to make sure things are going like planned. They could detect any problems or issues that are likely to arise and correct it, before they make a lot of products for everyone. This is incredibly useful step which in turn saves time, money and ensures that the final result will look its best.

Our work should not take long and sometimes the process of creating new things is really tardy. Thats why its so important to turn what we have in mind into an real thing as soon as possible. These days, we can produce prototypes in just a matter of hours with the help of contemporary machines and technology. The speed of this process is crucial because it allows the promotion and development of new products to people faster. Gone are the days when we had to wait for those ideas, sometimes weeks or even months.

Product making is incomplete without machining. It enables us to turn our ideas into things we can actually use in the world. We are even able to craft prototypes which mimic just about exactly the final product that we want to sell or share using correct machines and methods. This allows us to ensure our ideas are functional and helpful for the people who will be interacting with them. How thrilling to imagine that an idea of ours might transform into something useful, or practical, in the life of someone else somewhere?

In addition to automation and machining equipment, we also have a professional purchasing team, and we have prototype machining a vast source pool of suppliers for standard parts, as well as outsourcing surface treatment and heat treatment.

We have a total quality control and prototype machining participation. From the initial quality prevention to the more advanced product, it is a stringent quality process. Testing of the product is split between raw material testing tests for processing, and the final test. Our testing equipment is extremely comprehensive, the most important equipment is CMM projector, altimeter tester, spectrometer and the list goes on. We have a variety of foreign-funded and domestic companies. It also has passed the various layers of audits.

We have more than 14 years of experience processing and prototype machining machine tools, like CNC milling, CNC turning grinding machine, EDM wire cutting etc. Multi-process equipment is our forte.

Our technology is supported by experienced designers. Our designers have years of experience in the field of mechanical design. Our designers have more than prototype machining of experience in design. They've done process improvement, fixture design and equipment design.