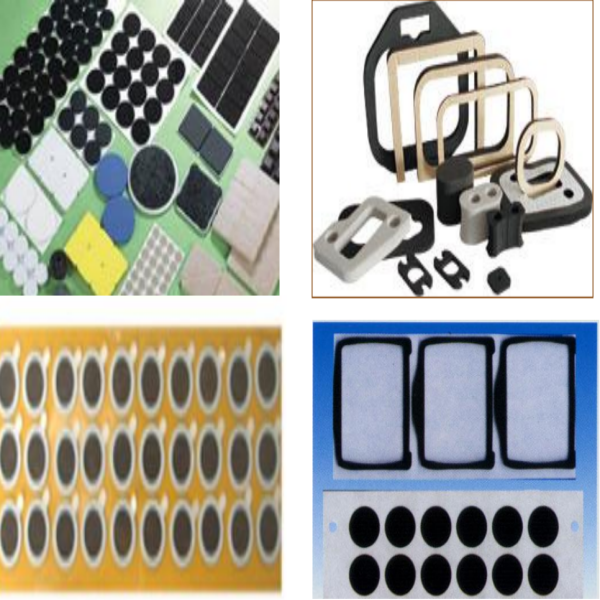

We use so many important things in daily life and probably not even know they exist. One of them is called precision die cutting AdditionallyGiving Answer for Precision Die Cutting Parts All of these components come to pass in any number of products that employ them in daily objects like cars, toys or electric appliances. They play a vital role in helping these things to perform effectively and perform their duties accordingly. This text is going to clear you, precision die cutting parts are vital and how can the deal be fabricated by these according to your demands?

Die cutting is done using a machine called die cutter, it dies cut the parts. Needless to say, this machine is the latest in technology and it can cut very gently but also with absolute precision. It's a quality check that uses the size of every piece to make sure everything fits together just so. The die cutter used a sharp blade to cut the shapes out of pieces. Because of this level of detail, every part is identical to the next and it therefore greatly streamlines mass production at factories where they can make tens of thousands without any faults

So, in the end there are many industries methodology is very accurate and fast who using precision die cutting technology. It could be life-saver for you as company saves time and money for it. These parts are all built with a consistent build which will further enhance the overall quality of your finished product This allows manufactures to produce complex forms many of which would be difficult if not impossible to replicate using other processes. The electronics industry depends on these specialized shapes as well, since a broad variety of gadgets are based specifically.

So what comes next The sort of applications for precision die cutting parts are innumerable - these range vary from automotive, to aeronautics and all the way up at architecture. On the other hand, they should be sturdy as these parts of a motorcycle helps in keeping all others running safely. They also inspect their work to ensure every part is of the required quality Quality assurance is vital, because when a quality component encounters far less repairable issues and can function at the same time more successfully for longer phases.

Meanwhile, at the production end of things should be a product that is orders of magnitude more performant if it utilizes precision die cutting parts. If every part is made perfect, the low probability in breaking will longer its product life span. It enables the production of an unlimited range of intricate shapes and patterns that are necessary in most product designs. For example by way of medical equipment, precision in this industry very details even the slightest mistake can cause safety problems. As a result, medical devices must rely upon absolutely precise components to keep them running in accordance with the highest order of function and safety.

Precision is all important in die cutting parts manufacturing. This maintains that each part which is being made repeatedly are of the same size and shape so as not to waste material along with reducing production time. This precision also means that the final result is of longer lasting better quality. For manufacturers, this requires capital expenditure on complex die cutting equipment and a commitment to high quality standards. So, these can also be positive that anything and everything is made perfectly as well the things they cook are important.

Our technology is supported by professional designers. Our designers are experts in mechanical design. Our designers have more that 20 years experience in the field of design. They've been involved in process improvement, precision die cutting parts as well as equipment design.

We have more than precision die cutting parts years of experience processing and complete machine tools, including CNC milling, CNC turning, grinding machine EDM wire cutting etc. Multi-process equipment is our forte.

Complete quality control is achieved by full involvement. From the very beginning, quality prevention to the final product, we follow a strict quality control process. The product testing is divided into raw material testing, the testing of processing and finally testing. Our testing equipment is also very precision die cutting parts, the main equipment comprises CMM altimeter, projector, hardness tester, spectrometer, and other such equipment. We are a partner with a lot of domestic and foreign-funded companies. We also have passed through their different layers of audits.

In addition to automation and machining equipment, we also have a professional purchasing team, and we have precision die cutting parts a vast source pool of suppliers for standard parts, as well as outsourcing surface treatment and heat treatment.