Opting for CNC milling in Runeham means subtractive manufacturing sticks to more traditional methods (subtractive and additive) by cutting the shape of your component out from a block or bar using a computer-run machine. This type is a computer numerical control machine that can produce metal parts in various shapes and sizes. And it does this with good accuracy, meaning the metal parts will fit well when they're made.

Why Use CNC Milling Machines One major reason for this is the high speed and accuracy at which these machines work. They operate by following the instructions of a computer in an exact manner as they are written. In other words, you can create metallic components without doing the entire work by hand which is a time-taking and strenuous process. Using CNC milling machines, you can save time and work on other pressing tasks.

Long story short - if you are in the market for a CNC milling machine, it can be challenging to get an ideal one, especially when all these machines look equally great from outside and operate on the same principles. There are some key things to think about in selecting. This involves assessing how large the machine is and whether it will fit in your working environment. Then, check the types of metal this machine can work on. Different machines are better with different metals. Electric may not need to be fast but efficiency in operation and the speedy cutting is another factor aid as an addition. Finally, also consider the price of machine and its cost within your budget.

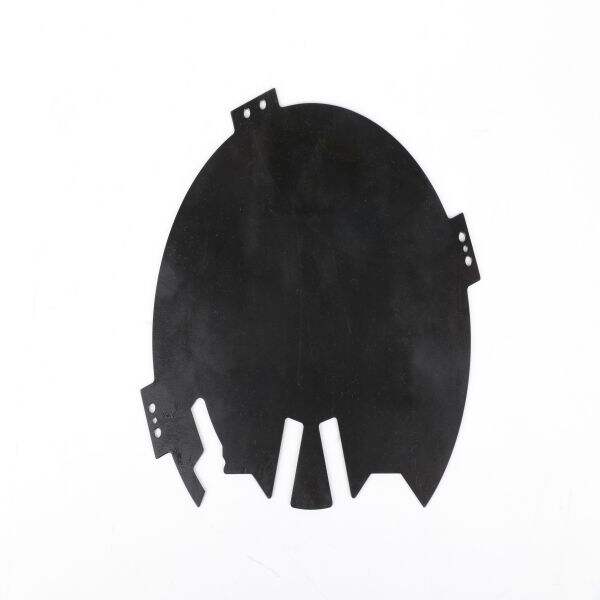

You can machine to depth uniformity depending on the need through a wide range of cutting tools you will be using in your CNC milling. It means selecting the proper cutter or drill for what you are trying to make. Tools are designed to do a specific job: they either help get work done quickly or better-or both-and choosing the right one for the task at hand delivers superior results, full stop. Also, the machine needs to be done at skirmish speed so it works properly. Coolant is an essential subsequent step as well since its job to keep the device cool while it cuts into metal. This stops the machine from overheating and keeps it working fine.

An exciting aspect of CNC milling is that it provides the means to make items never before able to be created. This technology allows us to quickly and simply generate the most intricate shapes and designs. As a result, this opens up lots of opportunities in the production of different products both small and large components. How much variety can this technology bring to building things — it is mesmerizing.

We have a highly skilled purchasing team as well as a metal cnc milling pool of standard parts. We also outsource surface treatment and heat treatments.

Complete quality control is achieved by full involvement. From the initial quality prevention to the final product, there is a rigorous quality process. Testing of products is split into test of raw materials, process testing and testing for final products. The equipment used for testing is extremely comprehensive. It comprises metal cnc milling, altimeters, projectors and hardness testers, spectrometers and more. We collaborate with a range of foreign and domestic-funded companies. The company has also been through their various audits.

We have professional design engineers to metal cnc milling our technology. Our designers are skilled in mechanical design. Some of our designers have more than 20 years of experience in design. They've been involved in process improvement, fixture design and equipment design, among others.

metal cnc milling have more than 14 years of experience and the complete equipment for machining such as CNC milling CNC lathe, grinding machine EDM, wire cutting etc. We have a unique benefit for products that are multi-process.